Two steps forward. Three steps back?

It’s finally beginning to get warm here in CT and I am becoming more than a little anxious about what’s left to do as I prepare Pandora for launch. As I don’t expect (wish? pray? plan?) to put her up for another winter anytime soon, I have decided to tackle as many projects as possible while she’s covered and on the hard, so the list continues to grow even as I finish each project. This year the “getting ready for launch” has turned out to be more of a “refit” but the good news is that when she hits the water, she should be in great shape indeed.

When a boat isn’t fully covered, with protection from the weather, many of those need-to-do projects, the ones that might allow rain to get down below, somehow get put off. A good example is the Plexiglas companionway, a sliding hatch and three “boards” that secure the boat from intruders, people and water. Over the years they had all gotten very scratched and dull with use. They looked downright shabby.  A while back I purchased an automotive buffer to bring back the shine to the paint and headlights on my little Suzuki truck and it worked really well. I needed it to make the truck look better, which it did but, frankly, I never thought that I would use it again. BTW, this is a link to the buffer I selected. It’s a much better unit, and more expensive, than one of the cheap ones available from Walmart or West Marine. It’s variable speed and random orbital which minimizes swirl marks or burns in the finish, which is vital to getting a good outcome. It also works with higher quality pads, the same ones that the pros use.

A while back I purchased an automotive buffer to bring back the shine to the paint and headlights on my little Suzuki truck and it worked really well. I needed it to make the truck look better, which it did but, frankly, I never thought that I would use it again. BTW, this is a link to the buffer I selected. It’s a much better unit, and more expensive, than one of the cheap ones available from Walmart or West Marine. It’s variable speed and random orbital which minimizes swirl marks or burns in the finish, which is vital to getting a good outcome. It also works with higher quality pads, the same ones that the pros use.

A few days ago, it occurred to me that it might be effective in polishing the scratched Plexiglas companionway boards so I pulled one off of the boat and gave it a try. Along with the buffer, I had purchased a set of three 3M polishing compounds that are progressively finer. The first in the series, and most aggressive, is labeled “compound” with the next two finer still, and when used in series, they are designed to bring a high shine to car paint.  In this instance, I decided to skip the middle grade and went from the most aggressive compound to super fine, on both sides of the panels. The whole process didn’t take long at all, less than an hour, and the difference is striking. I also used the compound to shine the stainless, with a rag. I am really happy with the result and it was surprisingly easy to do.

In this instance, I decided to skip the middle grade and went from the most aggressive compound to super fine, on both sides of the panels. The whole process didn’t take long at all, less than an hour, and the difference is striking. I also used the compound to shine the stainless, with a rag. I am really happy with the result and it was surprisingly easy to do.  I have mentioned in a prior post that I was replacing all of the old, inefficient fluorescent fixtures with LED. Yesterday I installed the new fixtures in the cockpit. I decided to use a version that is smaller than the ones I selected for use below decks as I am hoping that they will not be too bright. I had a hard time identifying a model that would work on 24v but these are good for both 12v and 24v. Only a few years ago it was very difficult to find dual voltage fixtures and bulbs but they have become much more affordable and now are available in a nice warm white, 3,000k, which looks great.

I have mentioned in a prior post that I was replacing all of the old, inefficient fluorescent fixtures with LED. Yesterday I installed the new fixtures in the cockpit. I decided to use a version that is smaller than the ones I selected for use below decks as I am hoping that they will not be too bright. I had a hard time identifying a model that would work on 24v but these are good for both 12v and 24v. Only a few years ago it was very difficult to find dual voltage fixtures and bulbs but they have become much more affordable and now are available in a nice warm white, 3,000k, which looks great.

All of the new bulbs and fixtures i am using are from DR LED. They have an extensive selection of LEDs for nearly any marine application. Their site looks like some kid set it up but, never the less, they have very broad range of great products. I do fear that even in red mode, and these fixtures are both red and warm white, may be too bright to use when on passage at night but I guess I’ll have to see how it goes. However, they should come in handy on buggy nights in Maine this summer. Fortunately, when we are in the Caribbean, there isn’t much of a problem with bugs unless we anchor too close to shore. It’s probably because it’s always blowing at least 20kts and there aren’t too many no-see-ums that can fly against a gale.

The old fixtures that I pulled out are a lot larger and I didn’t know what to do about the holes from the old fixtures so I just put in round head screws.  I have struggled to find LED replacement bulbs for the many halogen fixtures in the cabin that fit as most G4 LED replacement bulbs are not designed for use with a dimmer or are too big. Fortunately, Dr LED also makes a terrific little bulb that is small enough to fit in most any fixture, is very bright and yet dims well. These tiny bulbs are not cheap but they are a lot less expensive than replacing the entire light unit.

I have struggled to find LED replacement bulbs for the many halogen fixtures in the cabin that fit as most G4 LED replacement bulbs are not designed for use with a dimmer or are too big. Fortunately, Dr LED also makes a terrific little bulb that is small enough to fit in most any fixture, is very bright and yet dims well. These tiny bulbs are not cheap but they are a lot less expensive than replacing the entire light unit.  Well, there’s still plenty to do to get Pandora ready as I work my way through the list, one step at a time. Unfortunately, the list is long and it continues to grow at least as fast as I check items off.

Well, there’s still plenty to do to get Pandora ready as I work my way through the list, one step at a time. Unfortunately, the list is long and it continues to grow at least as fast as I check items off.

I expect that my new cabin heater will arrive this week so I can begin that installation. It’s the type that uses waste engine heat, much like a car heater, to warm the cabin. This will come in handy when we are in Maine or when I am motor sailing in the fall or on rainy days. I already have a diesel heater that operates independent of the engine, but I thought it would be nice to have an engine driven option as well. In addition, it is higher output, 30,000 btu, so it should warm things up quickly.

As an added bonus, the engine was set up for this type of heater when the boat was built so I don’t have to worry about any plumbing, just a simple extension of the engine heater hoses and electrical hookups. Also, as a special bonus, this particular style of heater isn’t terribly expensive as they are designed for use in trucks and commercial fishing boats. For sure, if they were built for marine use… well, they’d be twice, no make that three times as expensive. This is the unit I selected from Summit Racing but in 24v.  I also purchased a length of 3″ duct work and two outlets. I’ll be installing the unit and vents under the settees in the main cabin forward of the galley, hopefully, this week.

I also purchased a length of 3″ duct work and two outlets. I’ll be installing the unit and vents under the settees in the main cabin forward of the galley, hopefully, this week.  It’s always challenging to tackle projects on Pandora as the process, more often than not, feels more like a scavenger hunt, trying to find the right parts and not knowing where to get them. It is especially complicated when the parts are electrical as the boat is wired for 24v which usually means special order. As there were only three Aerodyne 47s built, I can’t just contact another owner to see how they might have solved a similar problem. For my last boat, a SAGA 43, there were more than 50 built and there was a very active owner’s forum with a number of owners who knew their boats inside and out and always had a quick answer to most any question.

It’s always challenging to tackle projects on Pandora as the process, more often than not, feels more like a scavenger hunt, trying to find the right parts and not knowing where to get them. It is especially complicated when the parts are electrical as the boat is wired for 24v which usually means special order. As there were only three Aerodyne 47s built, I can’t just contact another owner to see how they might have solved a similar problem. For my last boat, a SAGA 43, there were more than 50 built and there was a very active owner’s forum with a number of owners who knew their boats inside and out and always had a quick answer to most any question.

Still to come will be re-bedding some of the deck hardware and yesterday I finally opened up all of the headliner under the traveler for the boom, so I now know exactly where the bolts are located and they appear to be easy to reach. The traveler has been the source of a persistent leak so now I know how to solve that problem, if I can only get the traveler off. Now I know that it will be easy to get at all the bolts but will it be easy to remove after all these years? Wish me luck.

I’ll also be continuing to work on the job of re-covering much of the headliner, some I’ll do myself, and the rest I’ll be hiring out.

So, here I am, May is only a little more than a week away and I still have tons to do. I’ll admit that the process to date has felt like two steps forward and one step back. I guess that’s what working on boats is all about. Perhaps my best wish will be that it not be two steps forward and three, or worse, steps back.

Well, it’s been a long cold winter, well at least compared to the Caribbean, but at least I’m moving in the right direction.

However, don’t ask me about that pesky mast “step”. Talk about steps backward…

But hey, the companionway is looking great and there are two new lights in the cockpit. That’s progress, right?

It’s been a real treat to spend a week with them, here and near their home in Oakland. They live in a lovely little studio apartment with their dog Mila. It’s way to small for us to stay with them, so off to an Air B&B for us. It’s an expensive area so I won’t comment on where we’ve been staying. Let’s just say that today’s view, well, it’s better.

It’s been a real treat to spend a week with them, here and near their home in Oakland. They live in a lovely little studio apartment with their dog Mila. It’s way to small for us to stay with them, so off to an Air B&B for us. It’s an expensive area so I won’t comment on where we’ve been staying. Let’s just say that today’s view, well, it’s better. There’s even a root cellar, or is it a Hobbit House?

There’s even a root cellar, or is it a Hobbit House?  The view from the deck on the main house, where we are staying, is pretty spectacular.

The view from the deck on the main house, where we are staying, is pretty spectacular.  From the northern part of the property you get a pretty good feel for the scale of the place. You can barely see the main house peaking out from the trees on the left.

From the northern part of the property you get a pretty good feel for the scale of the place. You can barely see the main house peaking out from the trees on the left.  These trees to the left on the above photo look like they have had to work hard to grow here. Craggy and I expect very old.

These trees to the left on the above photo look like they have had to work hard to grow here. Craggy and I expect very old.  Out on the point, near the edge of the cliff, there are some wonderful spring flowers. These low lying fleshy plants grow everywhere.

Out on the point, near the edge of the cliff, there are some wonderful spring flowers. These low lying fleshy plants grow everywhere.  Love the dwarf iris, not more than 6″ tall.

Love the dwarf iris, not more than 6″ tall.  Near the northern property line, is a

Near the northern property line, is a  Anyway, back to the flowers. I have no idea what this is but it is impressive with a flower stalk that is over 4′ tall.

Anyway, back to the flowers. I have no idea what this is but it is impressive with a flower stalk that is over 4′ tall.  These clusters are on a bush along with dozens more make for quite a show.

These clusters are on a bush along with dozens more make for quite a show.

Nice spot. Mila waiting for lunch to arrive. Melody in a lovely hat. I just love hats.

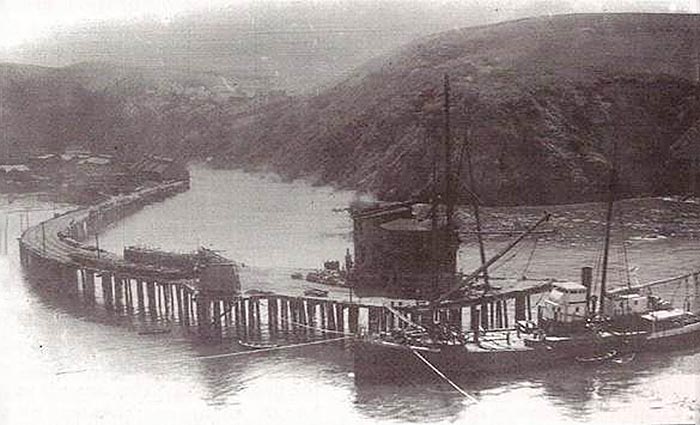

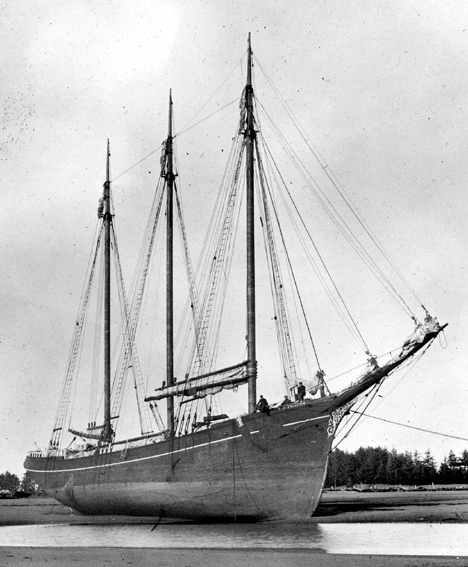

Nice spot. Mila waiting for lunch to arrive. Melody in a lovely hat. I just love hats.  The Pacific coastline is remarkably rugged, with many miles between ports. By the mid 1800s, this area was a major source of lumber, shipped all over the world and a major source for the wood used to rebuild San Francisco following the devastating earthquake of 1906. This photo does suggest that they needed a lot of lumber.

The Pacific coastline is remarkably rugged, with many miles between ports. By the mid 1800s, this area was a major source of lumber, shipped all over the world and a major source for the wood used to rebuild San Francisco following the devastating earthquake of 1906. This photo does suggest that they needed a lot of lumber. Lumber schooners, mostly with two to three masts and easily maneuvered, were able to pull into just about any spot in the coastline that offered even a small amount of protection from the ocean swells. These harbors, such as they were, were known as “

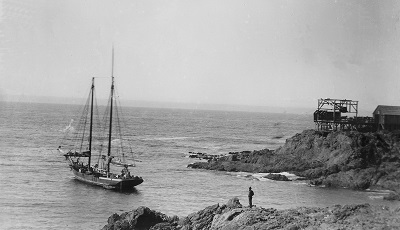

Lumber schooners, mostly with two to three masts and easily maneuvered, were able to pull into just about any spot in the coastline that offered even a small amount of protection from the ocean swells. These harbors, such as they were, were known as “ As close as we are to SF, about 3 hours by car, this areas once felt a lot more remote when it was only accessible by boat or stagecoach. In many ways, it still feels far away and very primitive. Well, primitive perhaps but with some really nice places to eat out and don’t forget about those wonderful wineries that are so close.

As close as we are to SF, about 3 hours by car, this areas once felt a lot more remote when it was only accessible by boat or stagecoach. In many ways, it still feels far away and very primitive. Well, primitive perhaps but with some really nice places to eat out and don’t forget about those wonderful wineries that are so close. Their dog Mila loves surveying all that she can see. “Hey mom and dad, I’ll bet that cove is one of those Dog-Hole Ports. Am I right?”

Their dog Mila loves surveying all that she can see. “Hey mom and dad, I’ll bet that cove is one of those Dog-Hole Ports. Am I right?”

I expect that these structures did not last very long with the relentless pounding of ocean waves. However, with low cost labor along with cheap and abundant building materials, I doubt that it mattered.

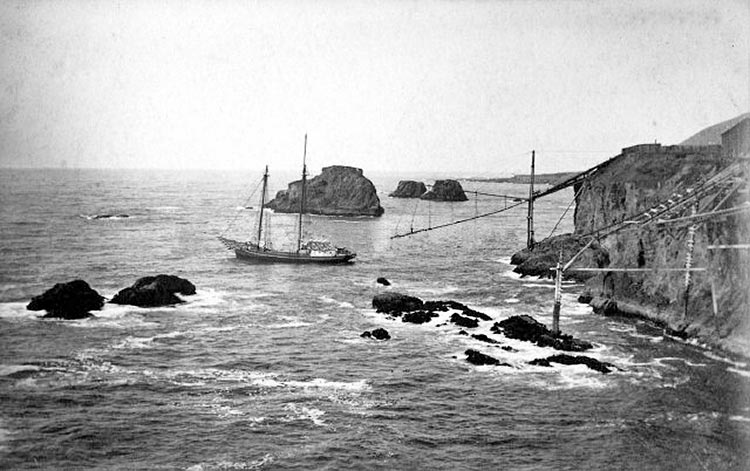

I expect that these structures did not last very long with the relentless pounding of ocean waves. However, with low cost labor along with cheap and abundant building materials, I doubt that it mattered. The only way, in those areas, to get materials down from high on the cliffs, was to use long lines strung from the top of the cliff or lumber shoots designed to slide boards down to the waiting schooner far below.

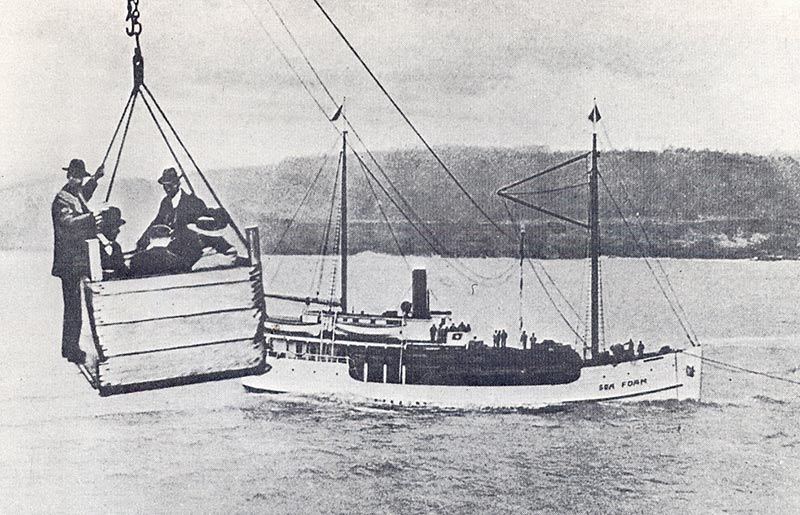

The only way, in those areas, to get materials down from high on the cliffs, was to use long lines strung from the top of the cliff or lumber shoots designed to slide boards down to the waiting schooner far below.  As technology improved, schooners made way for steam powered freighters but creativity was still needed to board freight and passengers. “Don’t worry little lady, I’ve done this hundreds of times.”

As technology improved, schooners made way for steam powered freighters but creativity was still needed to board freight and passengers. “Don’t worry little lady, I’ve done this hundreds of times.” The schooners that served this area had to be very maneuverable in order to safely make their way in and out of the tiny harbors along this exposed coastline. It was easier to load the ships from high cliffs than to try and transport lumber any distance over rough dirt roads to better harbors.

The schooners that served this area had to be very maneuverable in order to safely make their way in and out of the tiny harbors along this exposed coastline. It was easier to load the ships from high cliffs than to try and transport lumber any distance over rough dirt roads to better harbors. Over the years, she, along with a number of other vessels in the museums large collection, fell into an unfortunate state of disrepair but recently she has been fully restored.

Over the years, she, along with a number of other vessels in the museums large collection, fell into an unfortunate state of disrepair but recently she has been fully restored. Her stern was designed with openings that allowed the loading of long pieces of lumber below decks.

Her stern was designed with openings that allowed the loading of long pieces of lumber below decks.  In order to fit the maximum amount of cargo, she was designed with no bulkheads below decks.

In order to fit the maximum amount of cargo, she was designed with no bulkheads below decks.  There were once hundreds of these schooners moving lumber down the coast to San Francisco but she is now the last remaining one and it was nice to see her restored to better than new condition.

There were once hundreds of these schooners moving lumber down the coast to San Francisco but she is now the last remaining one and it was nice to see her restored to better than new condition. So, here I sit. It’s early April and I have a growing list of what has to happen to get her ready for the water. It’s like the old days before I retired but at least I don’t have to get up on a Monday morning and head to the office.

So, here I sit. It’s early April and I have a growing list of what has to happen to get her ready for the water. It’s like the old days before I retired but at least I don’t have to get up on a Monday morning and head to the office. At first I thought that the problem was limited to a few areas. No such luck.

At first I thought that the problem was limited to a few areas. No such luck. So, I decided to take nearly all of it down. It was a huge job and very messy. I consulted with Chad, the canvas maker that did a great job on my cockpit enclosure, to get advice on what to do. He suggested that I pull the vinyl down and then, with a wire brush on a drill, have at it. This is a view of the aft cabin, where I pulled down all of the vinyl. Then the drill…

So, I decided to take nearly all of it down. It was a huge job and very messy. I consulted with Chad, the canvas maker that did a great job on my cockpit enclosure, to get advice on what to do. He suggested that I pull the vinyl down and then, with a wire brush on a drill, have at it. This is a view of the aft cabin, where I pulled down all of the vinyl. Then the drill… The main cabin, post wire brush. Looks like a derelict boat. Depressing. And such a mess…

The main cabin, post wire brush. Looks like a derelict boat. Depressing. And such a mess… Over the weekend, I went to a sale at Defender, a discount marine supply company nearby. They have a once a year warehouse sale and it was mobbed. I purchased most of the lights I needed, along with a new

Over the weekend, I went to a sale at Defender, a discount marine supply company nearby. They have a once a year warehouse sale and it was mobbed. I purchased most of the lights I needed, along with a new  And, speaking of lights, I’ll also be replacing all of the inefficient fluorescent fixtures in the cabin and cockpit, along with all of the halogen bulbs in the overhead with LED bulbs and fixtures. The bad news is that the “footprint” of the old fixtures, and there are 9 of them, is larger than the new ones so that means that I’ll have to replace all the vinyl on other areas of the headliner that are basically fine to eliminate the old screw holes and stained vinyl in the areas around the old headliner. There are a LOT of fixtures to deal with. Fortunately, vinyl comes in many colors of “white” so we should be able to match the new to the old. Fingers crossed.

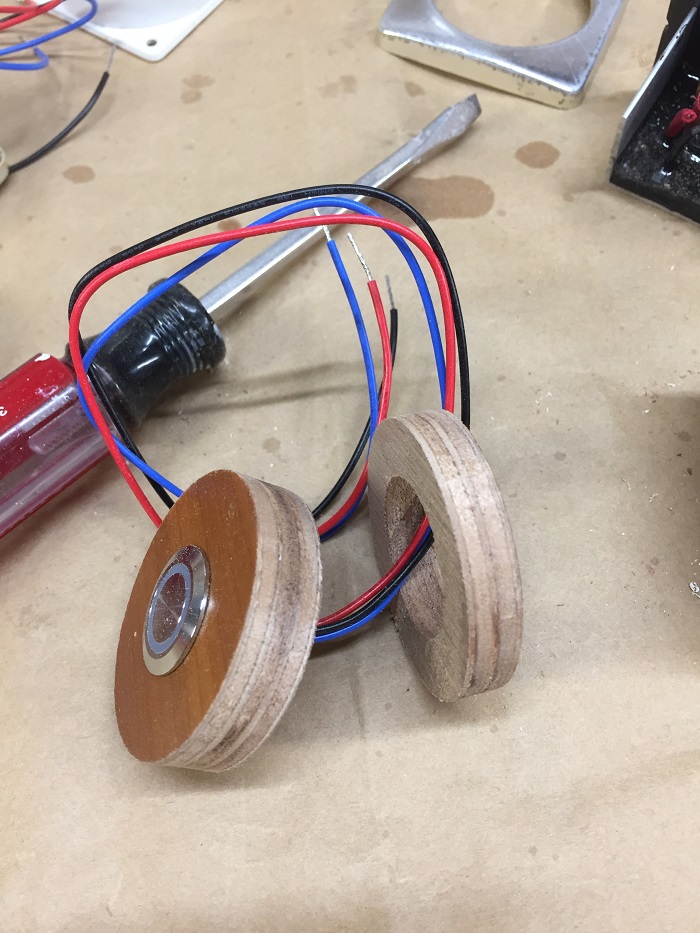

And, speaking of lights, I’ll also be replacing all of the inefficient fluorescent fixtures in the cabin and cockpit, along with all of the halogen bulbs in the overhead with LED bulbs and fixtures. The bad news is that the “footprint” of the old fixtures, and there are 9 of them, is larger than the new ones so that means that I’ll have to replace all the vinyl on other areas of the headliner that are basically fine to eliminate the old screw holes and stained vinyl in the areas around the old headliner. There are a LOT of fixtures to deal with. Fortunately, vinyl comes in many colors of “white” so we should be able to match the new to the old. Fingers crossed. In spite of my best efforts, I could not locate new dimmers that look anything like these and would fit in the same 2″ hole. So, I decided to just “remodel” and use the same dimmer casing. So, I made up wooden inserts from scrap plywood that matched the interior.

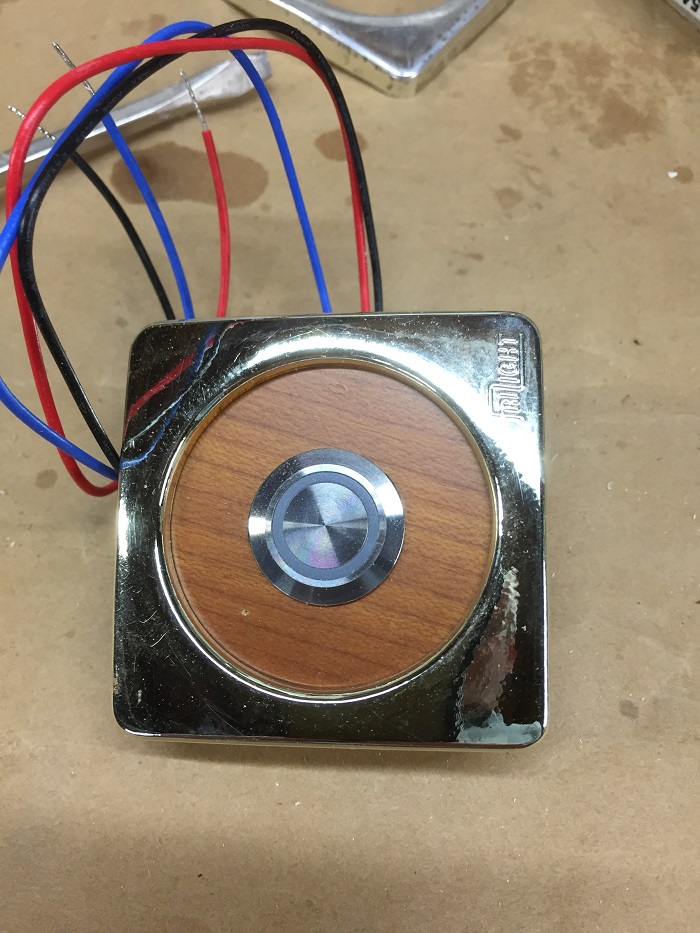

In spite of my best efforts, I could not locate new dimmers that look anything like these and would fit in the same 2″ hole. So, I decided to just “remodel” and use the same dimmer casing. So, I made up wooden inserts from scrap plywood that matched the interior.  The plan will be to glue the new touch dimmer into the old housing and it will look like this. Pretty neat, right?

The plan will be to glue the new touch dimmer into the old housing and it will look like this. Pretty neat, right?  I’m pretty pleased with myself, frankly. An elegant solution that will minimize effort in matching the current holes.

I’m pretty pleased with myself, frankly. An elegant solution that will minimize effort in matching the current holes. Oh yeah, one more thing. Pandora has electric toilets. Can you imagine, electric? And mixing electricity with, well, you know what, is a messy business. The toilet, head, has three electric motors and one failed on the aft head so I had to put in another. If you think that this looks expensive, it is. Fortunately, I was able to get it replaced under warranted. Let’s hope that if it decides to “poop out” it does so before a year. Motors on a head? Who knew?

Oh yeah, one more thing. Pandora has electric toilets. Can you imagine, electric? And mixing electricity with, well, you know what, is a messy business. The toilet, head, has three electric motors and one failed on the aft head so I had to put in another. If you think that this looks expensive, it is. Fortunately, I was able to get it replaced under warranted. Let’s hope that if it decides to “poop out” it does so before a year. Motors on a head? Who knew?  So, after a winter spent waiting for the weather to get warm enough to work on Pandora and time spent focusing on my “honey do list”, it’s time to get cracking and find a way to get Pandora back in the water and ready to cruise.

So, after a winter spent waiting for the weather to get warm enough to work on Pandora and time spent focusing on my “honey do list”, it’s time to get cracking and find a way to get Pandora back in the water and ready to cruise.